Technological innovation Non-pressurized desulfurization

Jingdong initiate World famous

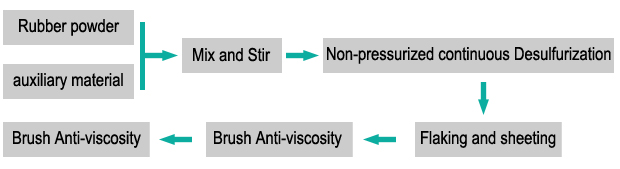

The new Non-pressurized continuous desulfurizing process and equipment for reclaimed rubber successfully developed by JingDong, it is an important innovation of the reclaimed rubber technology replacing the devulcanizer, and the excellent alternative of energy saving, environment protection and security for reclaimed rubber production.

| Production Technology |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| The reclaimed rubber production line |

| |

|

|

|

|

|

|

NO |

Name |

Numbers |

Total Power

(KW) |

Size(mm)/unit

(L)x(W)x(H) |

|

1 |

The preheating tank or pool |

1 set |

|

|

|

2 |

The exposure horizontal mixer |

1 set |

|

|

|

3 |

XL-159 Non-pressurized continuous desulfurizing machine |

1 set |

144 |

4950X6000X550 |

|

4 |

XK-450The rubber mixing mill |

2set |

55X2=110 |

5510X1900X1750 |

|

5 |

XKJ-480The rubber refiner |

1 set |

75 |

4790X2550X1780 |

|

The installed power(KW) |

330-350kw |

|

The number of worker/shift |

4 |

|

Occupied area(㎡) |

100-120 |

|

The capacity of reclaimed rubber(kg/h) |

500-700 |

|

The production line can be design in according to the client requirement. | |

|