|

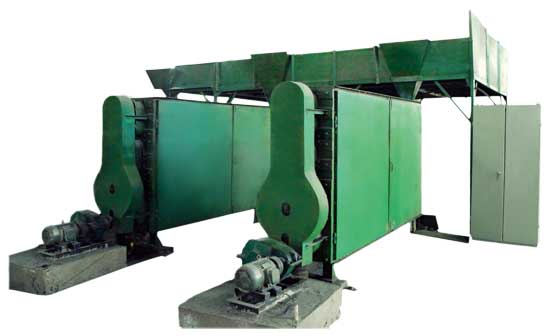

Product Description:

|

Model No: |

XL-159 |

| Overall dimensions: |

950X6000X550 mm |

|

Heating power: |

135KW |

|

Drive power: |

9KW |

|

Capacity(kg/h): |

500-700kg/h |

|

Power consumption (kwh/ton): |

140-150kwh/ton |

|

The number of worker/shift |

1 worker/shift |

Be used for desulfurization of rubber powder replacing the dynamic desulfurization tank, to achieve continuous working from input to output.

The advantages of Non-pressurized continuous desulfurizing machine

1) Wide application range

It can be used for devulcanizing and reclaiming all kinds of rubber and rubber powder which size is 24-30mesh.

2) Advanced technology

It is the production line type without stock dropping which reduces the worker’s labor intensity. The process parameters can be adjusted at any time with digital display and temperature control system.

3) High environment protection and safety efficiency

As the Non-pressurized continuous desulfurizing machine replaces the devulcanizer, there is no secondary pollution of waste liquid and waste gas, and non-pressure vessel with a high safety efficiency

4) Power saving and Low noise

The power cost for devulcanizing is saving 20% compared with the dynamic devulcanizer, and minimal vibration, low noise.

|